Draper, Utah - April 16, 2025

For decades, the materials behind our walls—drywall, OSB, plywood—have barely evolved. But a Utah innovator believes it’s time for a serious upgrade. HydroBlok is gaining traction among builders, distributors, and investors for its next-generation building board—one that could replace traditional drywall and sheathing materials with a single, high-performance composite.

Led by veteran entrepreneur Colin House, HydroBlok’s product has been proven in over 100,000 bathroom and shower installations worldwide, including major hotel chains like Marriott, Hyatt, Hilton, Ritz-Carlton, and St. Regis. Now, the company is expanding its reach far beyond bathrooms.

A Better Board from the Inside Out

HydroBlok’s core product features a closed-cell XPS foam interior, sandwiched between cementitious layers reinforced with fiberglass mesh. An optional white finish layer creates a smooth, paint-ready surface for drywall applications. The result: a 100% waterproof, mold-proof, Class A fire/smoke rated board that is four times more thermally efficient than gypsum- and wood-based alternatives.

“I’ve never seen a response like this in my career,” said House, who previously turned around Intellibed, a high-quality mattress company that was acquired by Purple in 2022. House attributes Intellibed’s earlier stagnation to poor messaging and weak distribution, not product flaws. Once he repositioned the brand and overhauled sales channels, revenue doubled year-over-year.

HydroBlok, he believes, has similar potential—but in much larger markets: drywall, sheathing/OSB, stucco, and more.

Lightweight and Labor-Saving

Beyond the performance stats, HydroBlok’s biggest competitive edge might be its weight—or lack thereof. The board is about two-thirds lighter than traditional gypsum drywall, which not only slashes shipping costs but also reduces on-site labor.

“A single 5/8-inch drywall sheet weighs about 105 pounds—and when you’re installing 300 of them on ceilings in multifamily projects, it’s brutal,” said Mikki Paradis, a Raleigh, North Carolina-based owner of a drywall company who recently adopted HydroBlok on a mid-sized residential project and plans to use it in more projects in the future.

“Hydroblok changes that. At a third the weight, it opens up the trade to a broader workforce, including women, who’ve historically been shut out of hanging heavy drywall simply because of the physical toll. If I were still hanging traditional 5/8th board like I was 20 years ago, I’d be seeing a chiropractor every week.”

In addition to being easy to handle, Paradis called out Hydroblok’s waterproof and mold-proof characteristics that make it an ideal choice for multi-family residential complexes.

“Water intrusion is the most expensive problem in residential construction—it leads to mold, mildew, and massive long-term damage. HydroBlok eliminates that risk as it is completely waterproof," added Paradis.

She added that HUD-financed projects, like many she works on, have strict durability and moisture standards. “HydroBlok doesn’t just meet those—it exceeds them.”

Faster Builds, Lower Costs

Builders also report significant efficiency gains. According to early feedback and internal testing, HydroBlok can reduce material and labor costs by up to 30%, and cut build times by as much as 50%, by eliminating the need for vapor barriers, waterproofing membranes, and extra insulation.

Jed Nilson, CEO of Nilson Homes in Utah, is piloting the product across multiple developments. His firm is part of Governor Spencer Cox’s $300 million affordable housing initiative, aimed at delivering 35,000 starter homes by 2028. Nilson Homes is the first Utah home builder to utilize this program, breaking ground on 275 attainable homes in the JDC Ranch development in Weber County. These homes are deed-restricted to remain owner-occupied for the first ten years, ensuring long-term affordability.

“We’re literally replacing a 4x8 sheet of drywall or OSB with a 4x8 sheet of HydroBlok,” Nilson said. “It’s simple, but the downstream impact is huge—fewer steps, faster timelines, and healthier homes.”

His crews have seen reductions in physical strain and jobsite delays. “The material is 60% lighter, it’s less wear and tear on the team. That matters in a labor crunch."

Nilson also pointed to time savings on stucco builds. “Replacing OSB with HydroBlok eliminates three or four traditional steps. That helps us align interior and exterior timelines and finish homes faster.”

Scaling Up—and Moving Onshore

Historically, HydroBlok imported from China and Thailand. In late 2024, the company began onshoring to Utah to reduce freight costs and respond to tariffs. "We were ahead of the curve," said House. “Manufacturing locally also lets us create jobs and innovate faster.”

HydroBlok’s Draper-based HQ now houses engineering, product development, and an Innovation Experience Center. “Once people see it, the value becomes obvious,” said House. “The real moment is when they realize how much faster and simpler construction can be.”

Industry Momentum

To build on its existing traction of the longstanding HydroBlok product experience in showers and bathrooms, HydroBlok Inc., a new entity, secured exclusive rights for all of North America and the ability to expand the product from showers to much larger markets.

Over the past year, the company has:

- Completed multiple industry certifications;

- Filed more than a dozen provisional patents and trademarks;

- Created builder- and contractor-specific specs and training;

- Held over 100 product validation meetings with architects, engineers, and construction firms;

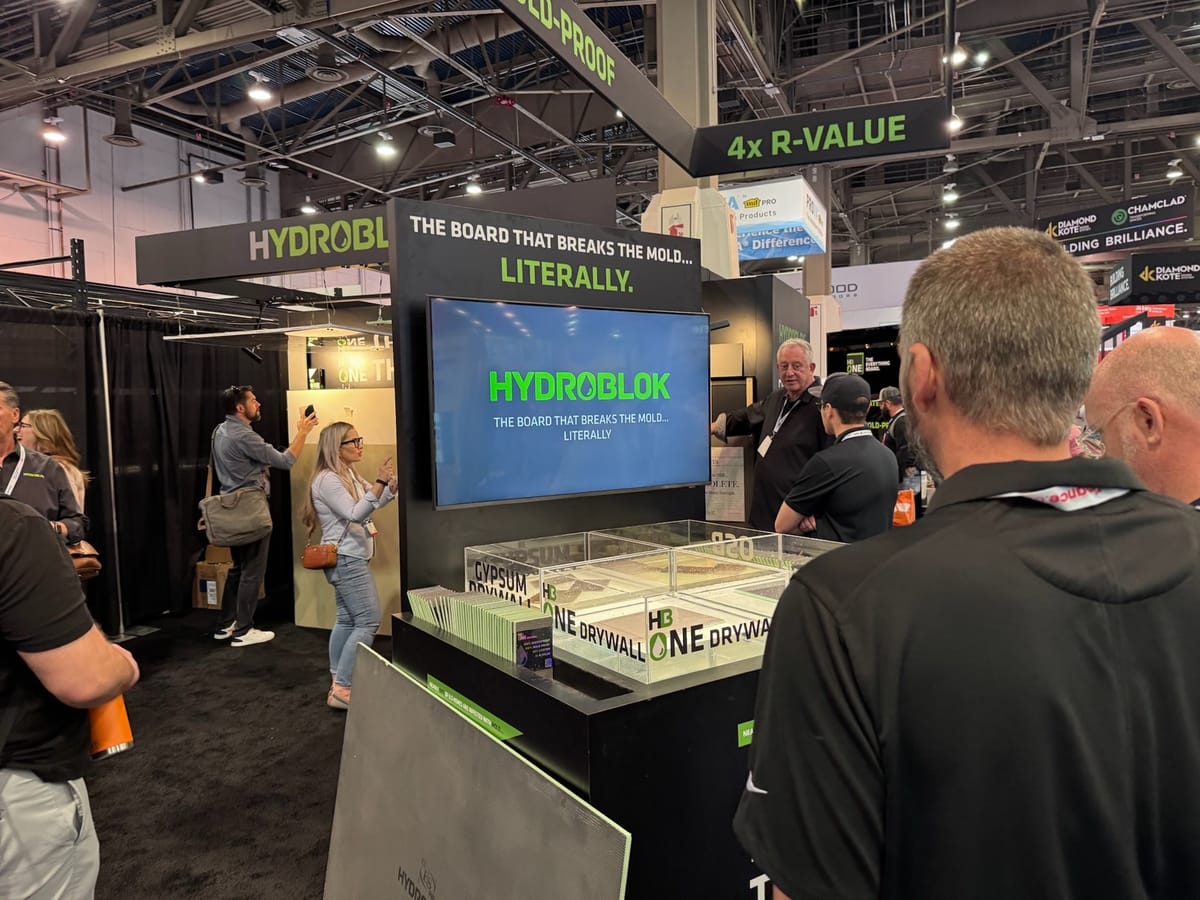

- Demonstrated at the 2025 International Builders Show in Las Vegas, where it was recognized as a “Top Innovation” at the show.

HydroBlok is now in advanced talks with national builders, distributors, and retailers. Early interest points to a product that finally checks all three boxes: performance, ease of installation, and cost efficiency.

A Composite Future

HydroBlok reflects a growing shift from legacy materials to advanced composites—just as airplanes moved from wood to aluminum to carbon fiber. “OSB replaced plywood. Now it’s time to replace OSB,” House said.

With proven field use, a seasoned leadership team, and a clear path to scale, HydroBlok may be one of the few construction innovations ready to meet the moment.

To learn more or schedule a tour of HydroBlok’s Innovation Experience Center, visit HydroBlok.com.